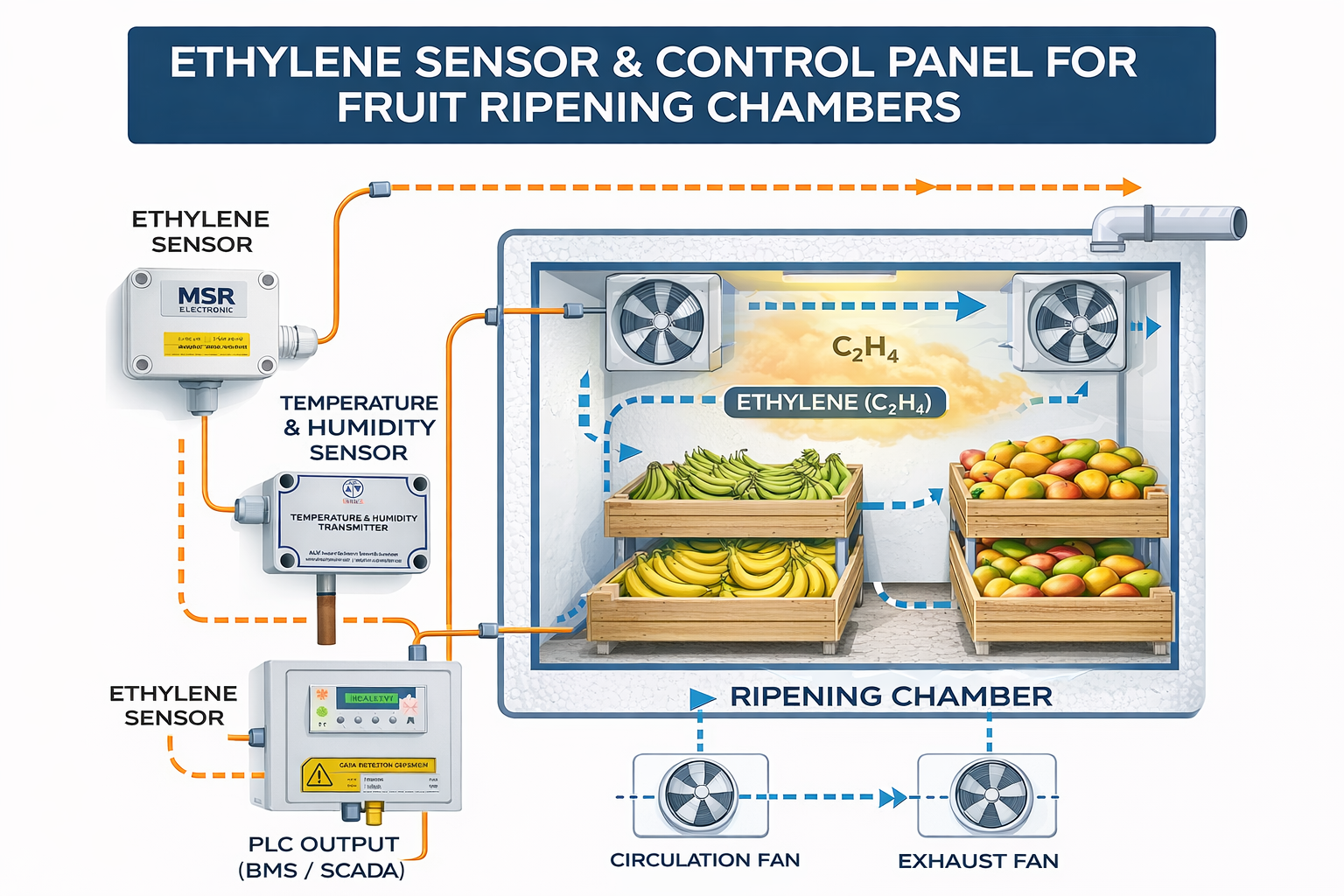

Ethylene Monitoring in Ripening Chamber

By ALVIFruit ripening chambers require controlled ethylene concentration (50–150 ppm) along with precise temperature (14–20°C) and relative humidity (85–95% RH) to ensure uniform, safe, and high-quality ripening.

Ethylene Gas Sensor for Fruit Ripening Chambers

The MSR Electronic Ethylene Gas Sensor is engineered for accurate monitoring and control of ethylene concentration inside controlled atmosphere and fruit ripening chambers.

Ethylene plays a critical role in initiating and regulating the fruit ripening process. Uncontrolled levels can lead to uneven ripening, spoilage, or safety risks. This sensor ensures precise ppm-level detection, enabling optimized ripening cycles and consistent fruit quality.

Key Features

- Continuous ethylene gas monitoring (ppm range)

- Robust industrial enclosure suitable for humid environments

- Compatible with PLC, BMS & automation systems

- Long-term stability and low maintenance

- Ideal for safety alarms and ventilation control

👉 Why TRH is Important

Even with correct ethylene dosing, improper temperature or humidity can ruin the batch:

- Too hot → uneven ripening, spoilage

- Low humidity → fruit dehydration & weight loss

- High humidity → fungal growth

Typical Applications

- Banana ripening chambers

- Mango & papaya ripening rooms

- Cold storage facilities

- Food processing & agri-infrastructure projects

- System Integration

The sensor can be seamlessly integrated with:

- PLC-based control panels

- Temperature & humidity (TRH) sensors

- Exhaust and circulation fan control

- Alarm and safety interlock systems

Resulting in uniform ripening, reduced losses, and compliance with food safety standards.

#FruitRipening #EthyleneSensor #ColdStorage #AgroTech #FoodProcessing #GasDetection #MSRElectronic #Automation #PLC